A metal floor deck Roll Forming Machine consists of an uncoiler, Coil Sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, and a supporter table. The corrugated profile sheet produced by this machine has high strength with big rib. It`s best to be used as the floor of high buildings, and the cost of such floor is low.

Features

High productivity

Stable forming and quality of final products.

Improved cutting method minimizes the tolerandce of cutting length.

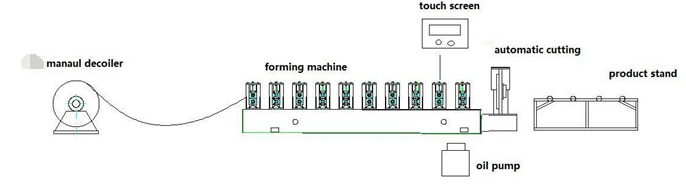

1.Processing flow diagram of machine

Manual Decoiler→ Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

| configurations | manual decoiler, guiding platform, main machine of roll forming, cutting device, electric motor, hydraulic station, Delta PLC control system, run out table |

| Material (This material is a little hard than normal material , so the machine need to be made according this material) | Minimum Thickness | 0.3-0.8 mm |

| Max Thickness | 1.0 mm |

| effective width | 1000 mm |

| Feeding width | 1200 mm |

The advantage of our roll forming machine:

1.Good quality: We have a professional designer and experienced engineer team.And

the raw material and accessories we use are good.

2.Good service: we provide the technical support for whole life of our machines.

3.Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4.Easy operation:All machine cotrolling by PLC computer controlling systerm.

5.Elegant apperance:Protect the machine from rust and the painted colour can be customized

6.Reasonable price:We offer the best price in our industry.

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

FAQ

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

Looking for ideal Floor Deck Machine Roll Forming Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Floor Deck Machine Metal are quality guaranteed. We are China Origin Factory of Roll Forming Machine Superb. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu