Clean Room Sandwich Panel Machine

Finished products:

Thickness:0.5-1.0 mm

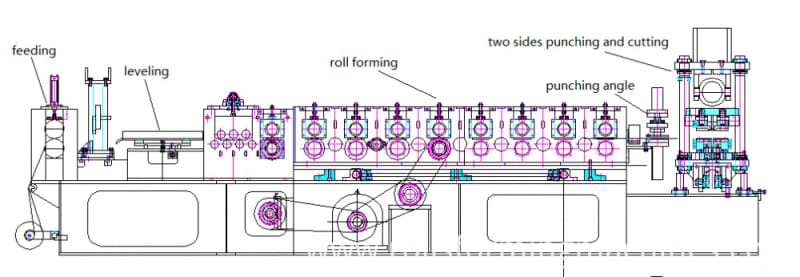

Roll Forming Machine production process

Decoiler - feed - leveling - roll forming - punching angle - shear and folding - output table

Working speed: speed: 8-12 m/min;

Feeder and leveling

This part will level coil to make sure it is neat clean and straight. Leveling uses 7 rollers, 3 upper rollers and 4 down rollers.

Feeder rollers: two sets

Roll forming machine

Size(L*W*H) : around 5.0 *1.5 *1.0 m

Power: 4kw

Forming roller station:10

Roller material:45 # steel after finishing quenching HRC 58-62 ℃, chrome plated

Shaft material:45 # steel finish

shaft diameter: ¢ 50 mm

Voltage:380V, 50HZ, 3 phase( customize)

Transmission: 1.0 chain

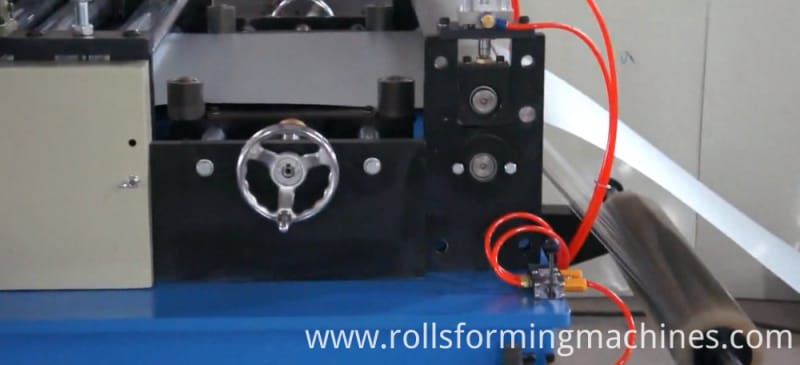

cutting and Bending Machine

(1) Cut mode: The host automatically stopped and then cut to length scissors,meanwhile,fold the end of plate side and The beginning of the next plate side,

cutting is completed, the host automatically run, to continue production.

(2) Cut material: GCR12, heat treatment and quenching HRC58-62 ℃

(3) cut length monitoring: automatic fixed-length cut

(4) cut length error: 3 ± 1.5mm

| Delivery | One 20 GP container needed Delivery:80 days |

1. One year, and we will provide the technical support for the whole life.

2. Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

3. Need one technicians.

4. Training time: one week (contains the time of installation and adjustment)

Looking for ideal

Sandwich Panel Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Room

Sandwich Panel Machine are quality guaranteed. We are China Origin Factory of Clean Room Sandwich Panel Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Coil Sheet

Mr. Cary xu

Mr. Cary xu