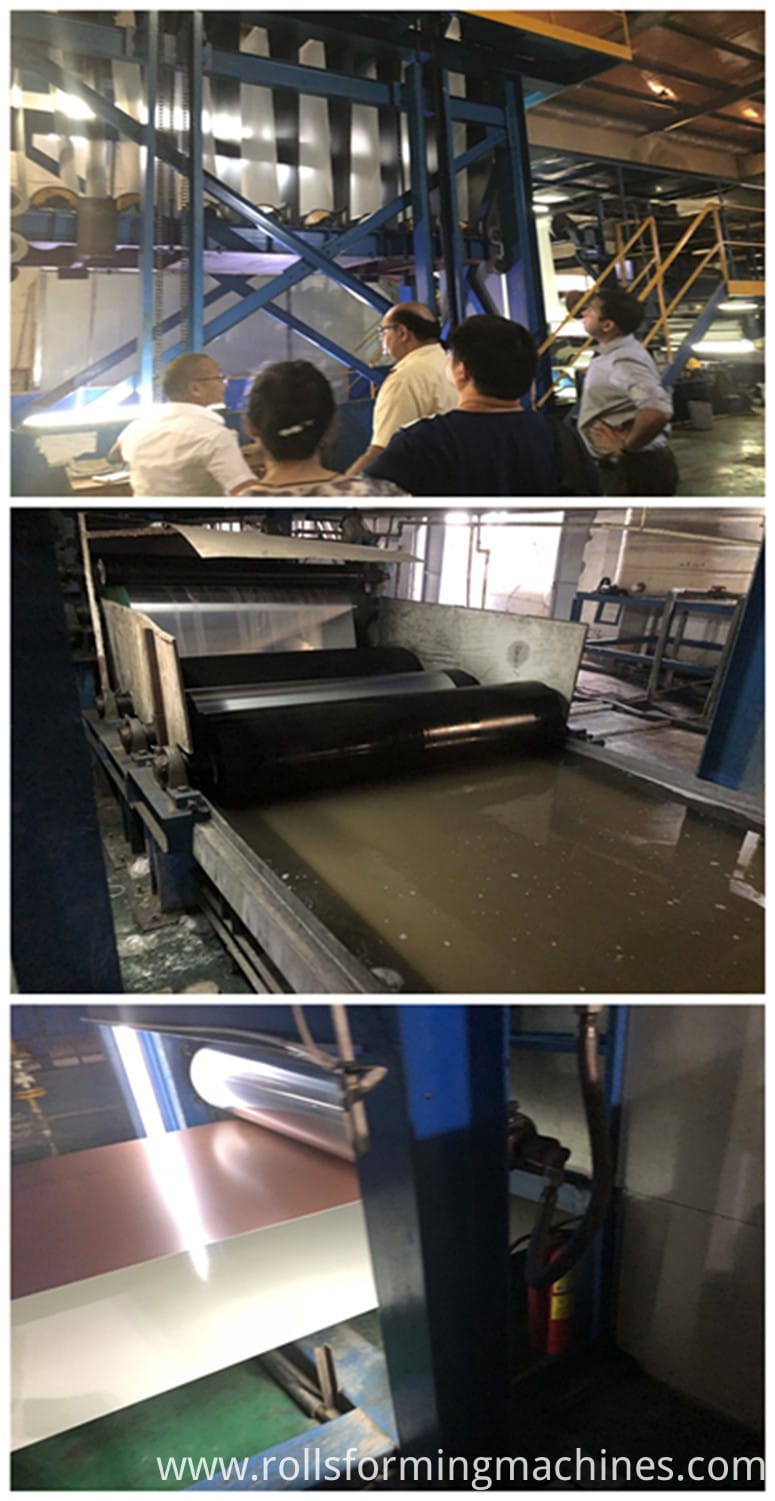

Aluminium Color Coating Line

Aluminum Coil color coating line is developed according to the market demanding, which could implement simultaneously coating at both sides. According to the different needs of customers, it can finish single coating at one side, single coating at both sides, dual coating at top side while single coating at under side, dual coating at both sides in one time. which consists of uncoiling section, pretreatment, process and coiling sections. It has the function of degreasing, chemical coating, double-coated and double baked (For finish coating it is equipped).

Color Coating Line General process flow

1#2# Uncoiler → steering pinch roller → steering roller →confluent pinch roller → inlet shear → sewing machine → press burr and pinch roller → 1# tension roller → inlet looper → 2# tension roller →degreasing → brushing → water washing → drying → chemical roller-coating machine → chemical-coating drying furnace → 1# deviation-correcting machine → 3# tension roller → initial coating unit → initial coating curing furnace → cooling unit → 2# deviation-correcting machine → dryer → 3# deviation-correcting machine → 4# tension roller → printing unit → fine coating unit → fine coating curing furnace → cooling unit → dryer → 4# deviation-correcting machine → 5# tension roller → outlet looper → 6# tension roller → pinch shear → steering roller → EPC deviation-correcting coiler → inspection → package → entering warehouse

1. Entry section operation

The aluminium coil is first removed manually before the feeding, and then placed on the No.1 or the crane No.2 on the coil car.

The manual shut-off coil strapping, coil car coil will start to uncoiler to uncoil in front, and then to the uncoiler, At the same time decrease coil car and return to the waiting position, ready to pick up a aluminum coil. The head of the aluminum coil is fed into the pinch roll with the aid of the payoff reel and the manual belt, and the strip is sent to the sewing machine before the sewing machine is waiting to be sutured.The rolled strip is rolled into the 1# bridle roll and then enters the looper. The entrance looper is vertical structure. It will release the stored aluminum strip to maintain the constant speed operation to make sure the contiuous process.

2.cleaning section

The strip enters the cleaning section after leaving the 1# Bridle roll and the inlet sleeve. The cleaning section includes chemical degreasing, roller brushing degreasing, washing and other processes; each process is equipped with a squeezing roller to ensure the relative stability of the tank fluid and the squeezing effect of the plate surface; the stability is enhanced, and the waste heat is used to heat the bath liquid.

3. chemical pre-treatment

The aluminium strip will be chemically pretreated to enhance adhesive and corrosion resistance between the coating and the substrate.

4. coating

The strip is finished by " primer coating, curing, cooling, precise coating, curing and cooling" process. When coating, the coating method, the speed of each roller and the roll gap should be determined according to the coating thickness required by the finished product. When the coating thickness changes, manual manual adjustment of the roll gap.

5. curing

After coating the steel strip, it enters the curing oven to be heated and solidified.The curing time of strip steel in the furnace is determined according to the parameters such as strip thickness, coating type, coating thickness and curing temperature. The furnace temperature is usually in the range of 250~400℃, and the maximum temperature of the strip surface is different when the furnace temperature is different.

6. Exit section

When the export looper is in normal operation, the strip is not stored. When the outlet section is cut, sheared, sampled and unloaded, the outlet sleeve is filled to maintain the constant speed operation of the unit process

section.

Technical Parameters

| Base coil | hot aluminium coil, aluminum alloy coil |

| Thickness of strip | 0.2-3mm |

| Width of strip | 800-1800mm |

| Outer diameter of aluminium coil | φ800-2000mm |

| Process speed | 20-120m/min |

| Thickness of coating | Max40μm |

| Thickness of printing layer | ≤1μm (oil ink or polyester) |

| Production capacity | 20,000-60,000 t/year |

Looking for ideal ACCL Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Aluminium Color Coating Line are quality guaranteed. We are China Origin Factory of Color Coating Line for Aluminium Coil. If you have any question, please feel free to contact us.

Product Categories : Metal Processing Line

Mr. Cary xu

Mr. Cary xu